What are the applications ?

Air handling and ventilation system inlets and outlets

Machine acoustics (air conditioning, ventilation, etc.)

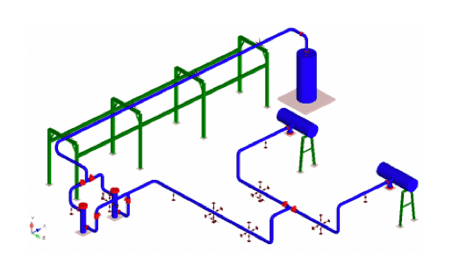

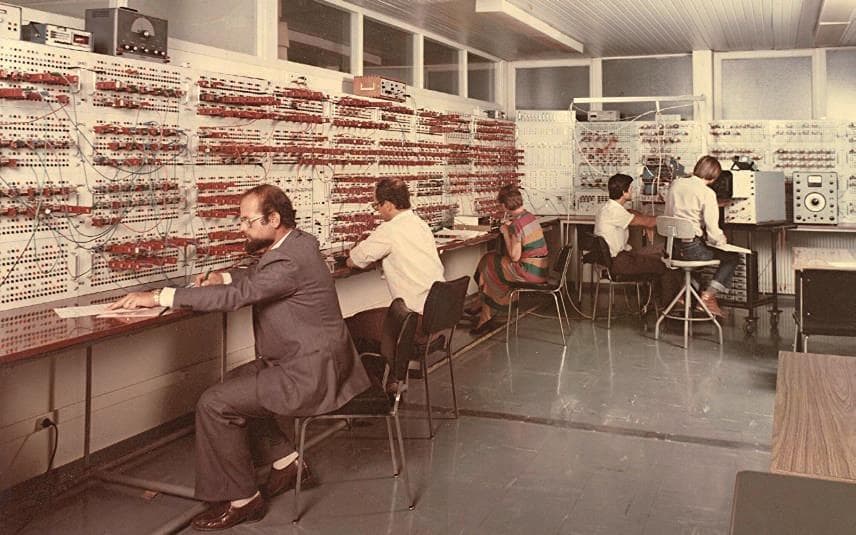

Pulsation and vibration

The pulsatory study

During the acoustic study, pressure pulsations and unbalanced forces are controlled using the following techniques:

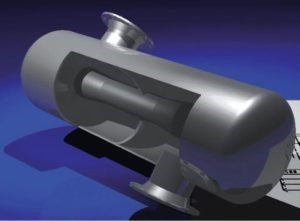

Acoustic filters such as empty volume or volume with internals

Frequency separation by optimising pipe cross-sections and/or lengths

Addition of resistive elements such as orifice restrictions

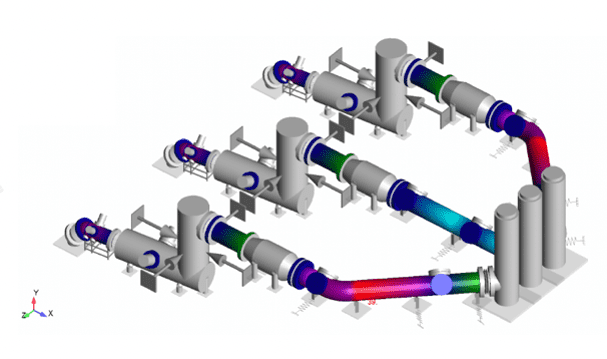

In accordance with API 618, the acoustic study provides information on :

Pulsating pressure

Unbalanced forces induced by pulsations

Pressure losses

Flow and power deviations

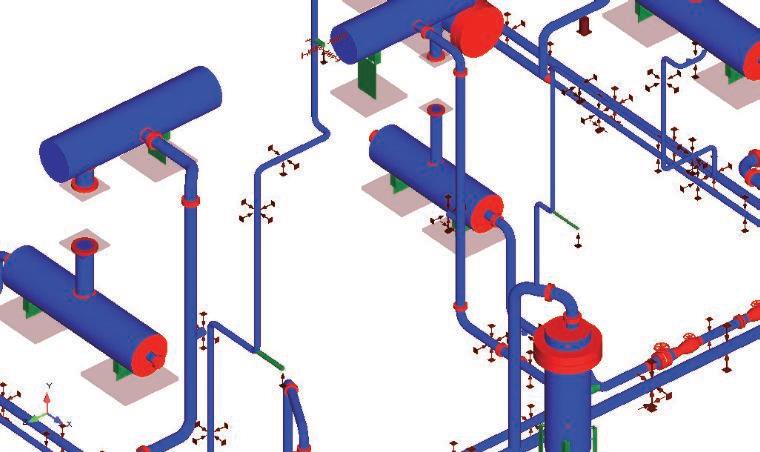

Study of mechanical response

The mechanical response study helps to optimise vibration and cyclic stress conditions by improving the design of pipe and boilerwork supports.

In accordance with API 618, the mechanical study provides information on :

Natural frequencies

Forced response vibrations and cyclic stresses