Our acoustic and technical training courses

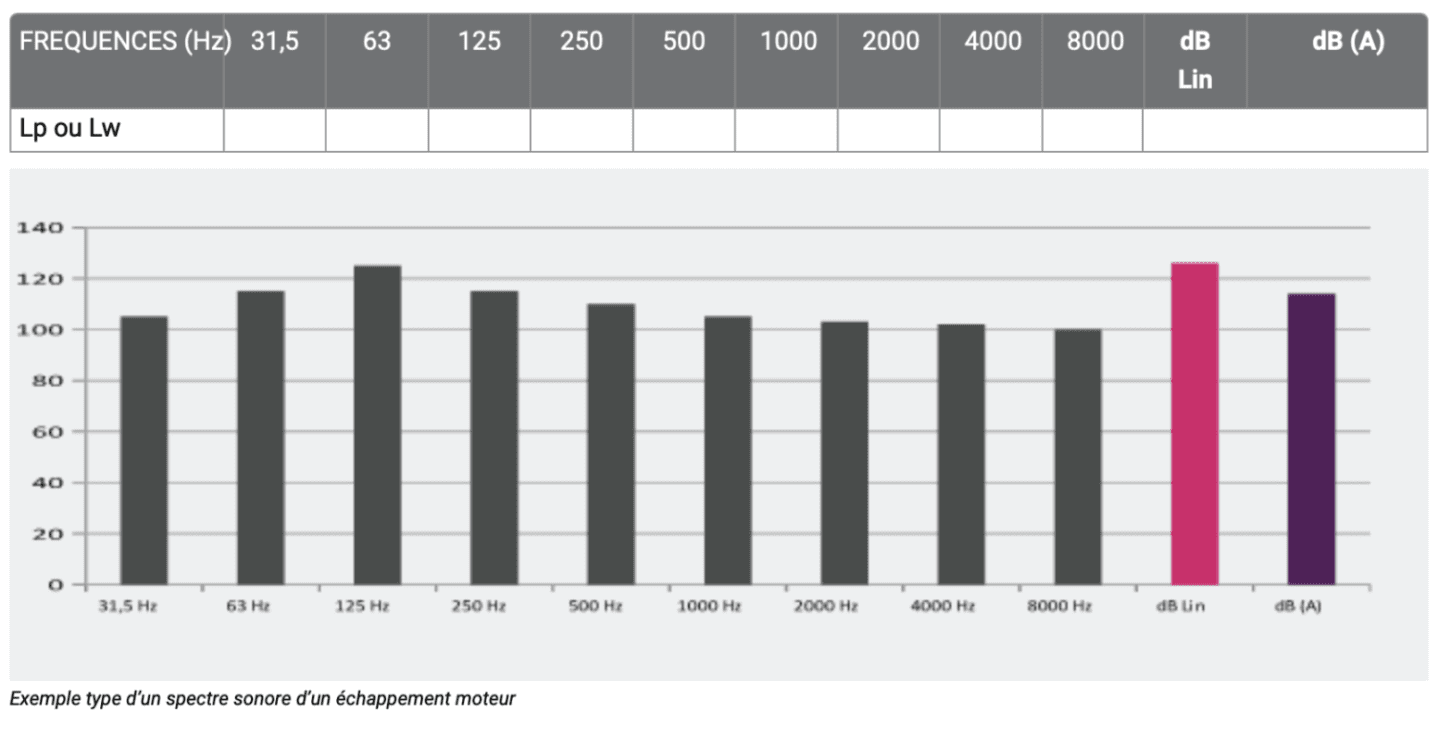

Operating principle of a Vent Silencer

There are a number of pressure-reducing systems used in industry to reduce pressure or discharge a pressurised flow (safety valve, pressure-reducing valve, etc.). The passage of a pressurised fluid through a restricted section (orifice, perforations, etc.) will cause the fluid to expand…

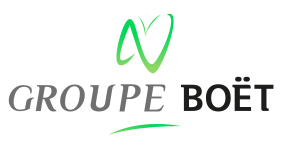

Operating principle of an Engine Silencer

Engine silencers are devices integrated into the exhaust line of internal combustion engines. They are designed to reduce the noise emitted by the engine while minimising pressure losses.